The 3.0-liter V6 diesel engine Mercedes OM 642 has been produced by the concern since 2005 and is installed on almost all models from the C-Class to the G-Class SUV and Vito minibuses. Also, this diesel engine is actively installed on Chrysler and Jeep models under its EXL index.

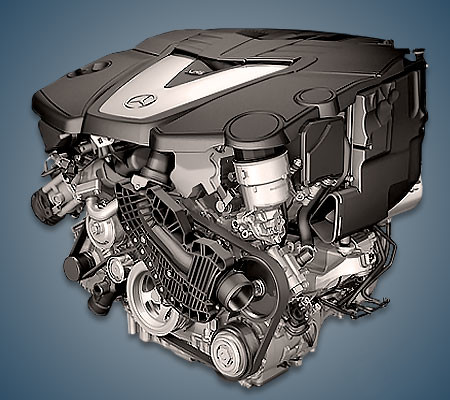

In 2005, the German concern Daimler AG introduced its first V6 diesel unit. By design, there is an aluminum block with a 72° camber angle and cast-iron liners, a pair of aluminum DOHC cylinder heads with hydraulic lifters, a timing drive in the form of a two-row chain, a Bosch CP3 Common Rail fuel system with piezo injectors and an injection pressure of 1600 bar, as well as a Garrett GTB2056VK turbine with an electric drive variable geometry and intercooler.

During the production process, the diesel engine was repeatedly upgraded and, when updated in 2014, received an AdBlue urea injection system, as well as a Nanoslide coating instead of cast iron liners.

Specifications

| Production years | since 2005 |

| Displacement, cc | 2987 |

| Fuel system | Common Rail |

| Power output, hp | 184 – 204 (DE 30 LA red. or 280 CDI / 300 CDI) 211 – 235 (DE 30 LA or 320 CDI / 350 CDI) 231 – 265 (LS DE 30 LA or 350 CDI) |

| Torque output, Nm | 400 – 500 (DE 30 LA red. or 280 CDI / 300 CDI) 440 – 540 (DE 30 LA or 320 CDI / 350 CDI) 540 – 620 (LS DE 30 LA or 350 CDI) |

| Cylinder block | aluminum V6 |

| Block head | aluminum 24v |

| Cylinder bore, mm | 83 |

| Piston stroke, mm | 92 |

| Compression ratio | 18.0 |

| Hydraulic lifters | yes |

| Timing drive | double row chain |

| Turbocharging | Garrett GTB2056VK |

| Recommended engine oil | 5W-30, MB 228.51/229.51 |

| Engine oil capacity, liter | 8.0 (passenger cars) 10.0 (Vito) 12.0 (Sprinter) |

| Fuel type | diesel |

| Euro standards | EURO 4/5/6 |

| Fuel consumption, L/100 km (for Mercedes ML 320 CDI 2010) — city — highway — combined |

12.7 7.5 9.4 |

| Engine lifespan, km | ~450 000 |

| Weight, kg | 220 |

The motor has an aluminum body with intersecting struts. The cylinders in it are equipped with cast iron sleeves, which contributes to hardening and operational reliability. The connecting rods are steel, and the crankshaft is made of heavy-duty material, with an extensive shaft bearing surface.

The engine crankcase is made of die-cast aluminum with a through cross strut and gray cast iron cylinder liners to help reduce engine weight. The injectors are designed as 8-hole nozzles. Optimized airflow intake and charge tracts improve charge changeover. The charge air cooler allows the charge air temperature to be reduced to 95° C.

Piezo injectors allow up to 5 injections per cycle. This helps to reduce engine noise while improving responsiveness and dynamics. The VTG turbocharger delivers both high power and high torque even at low revs. Electrically regulated turbocharger provides fast and accurate boost pressure control, keeping metering and boosting errors to a minimum.

Features of engine injectors:

- injection is controlled by the electronic control unit;

- injectors are made in the form of nozzles, have eight holes;

- pressurization is provided by a VTG compressor with variable turbine length;

- the intake manifold is equipped with an additional air duct;

To improve environmental performance, a cooled exhaust gas recirculation (AGR) system is used. Several details are involved in the operation of this system:

- the filter is restored without using additional elements;

- selective catalyst traps ammonia from diesel combustion, preparing the substance for a further reduction reaction;

- at the same time SCR acts as a filter that traps odors of sulfur, etc.

Disadvantages of the OM642 engine

- The most famous problem of this diesel engine is leaking on the heat exchanger gaskets, and since it is in the collapse of the block, replacing penny gaskets is not cheap. Around 2010, the design was finalized and such leaks no longer occur.

- The power unit is equipped with a reliable Bosch Common Rail fuel system, but its piezo injectors are very demanding on fuel quality and are also expensive. It is also worth noting the regular failures of the fuel quantity control valve in the injection pump.

- There are steel swirl flaps in the intake manifold of this power unit, but they are controlled by a servo with plastic rods that often break. The problem is greatly exacerbated by contamination of the intake due to the fault of a weak crankcase ventilation membrane.

- The Garrett turbine itself is very durable and runs quietly up to 300,000 km, except that the system for changing its geometry often wedges due to heavy pollution. Most often, the turbine is spoiled by crumbs from the destruction of the exhaust manifold welds.

- This motor is famous for frequent lubricant leaks and not the most durable oil pump, and since it is sensitive to oil pressure, it is not uncommon to turn the liners here.

In general, this V6 diesel engine turned out to be quite reliable and unpretentious. It does not even come close to the problems that arose on gasoline engines produced at the same time and installed on the same cars.