The 1.3 liter Nissan GA13 engine line was intended for the local market. The first carburetor versions were introduced in 1989, and with electronic injection they were assembled until 1999.

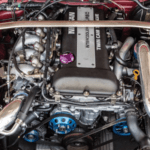

The engines of the GA13 family have a classic design for that time: a cast-iron block is combined with an aluminum head without hydraulic compensators. In the 12-valve version, there is one chain, and in the 16-valve version there are two at once: the large one goes from the intermediate shaft to the crankshaft, and the small one from it to both camshafts.

In total, 3 versions of the engine were produced with two different power systems:

GA13S – in this modification, an electronically controlled carburetor and only one camshaft for 12 valves. The first row of which opens with camshaft cams, and the second with rocker arms. Power 75 hp, torque 100 Nm.

GA13DS – here the carburetor is combined with a 16-valve block head and, accordingly, there are 2 camshafts. This gives it 79 hp and 104 Nm.

GA13DE – an advanced version received a DOHC 16v head and electronic fuel injection. This gives it 85 hp and 109 Nm.

The engine was installed on:

- Nissan Pulsar N14 in 1990 – 1995;

- Nissan Sentra 3 (B13) in 1990 – 1995;

- Nissan AD 2 (Y10) in 1990 – 1995.

Specifications

| Production years | 1989-1999 |

| Displacement, cc | 1295 |

| Fuel system | carburetor / injector |

| Power output, hp | 75 – 85 |

| Torque output, Nm | 100 – 109 |

| Cylinder block | aluminum R4 |

| Block head | aluminum 12v / 16v |

| Cylinder bore, mm | 71 |

| Piston stroke, mm | 81.8 |

| Compression ratio | 9.5 |

| Features | no |

| Hydraulic lifters | no |

| Timing drive | chain |

| Phase regulator | no |

| Turbocharging | no |

| Recommended engine oil | 5W-30, 5W-40, 10W-30, 10W-40 |

| Weight, kg | 143 (GA13DE) |

| Fuel type | petrol |

| Euro standards | EURO 1/2 |

| Fuel consumption, L/100 km (for Nissan Pulsar 1991) — city — highway — combined |

7.1 5.3 5.8 |

| Engine lifespan, km | ~300 000 |

Disadvantages of the GA13DE engine

- Especially often, owners of cars equipped with engines with a carburetor power system complain about floating engine speeds, and the reason for this is clogging of strainers and jets due to poor-quality fuel.

- On injection versions, the speed most often floats when the idle valve or the mass air flow sensor breaks. Sometimes cleaning helps, sometimes just replacing.

- The main problem of the GA series engines is the oil burner. It comes on long runs due to the occurrence of oil scraper rings. If you do not miss the moment, then you can get by with decarbonization, if not, then only a replacement. Sometimes a leaky gasket is to blame for engine oil consumption, which, by design, should not allow fuel and lubricants into the intake tract along with crankcase gases.