By 2007 Scania completely switched over to the production of unified Scania DC11 and 12 engines. At the same time, Scania DC 12 engines, in contrast to 11-liter engines, have an increased piston stroke and volume respectively. Also, the internal combustion engines differed in the size of the crankshaft crank and the length of the connecting rods.

Scania in-line engines are classics of the genre that have a future with regard to the further development of Scania engines. Inline diesel engines are installed on almost all models of long-haul tractors, trucks and Scania special equipment.

Specifications

| Manufacturer | Scania |

| Also called | DC 12 |

| Cylinder block alloy | cast iron |

| Fuel system | direct injection |

| Configuration | inline |

| Number of cylinders | 6 |

| Piston stroke, mm | 154 |

| Cylinder bore, mm | 127 |

| Displacement, cc | 11700 |

| Power output, hp | 340-470/1900 |

| Torque output, Nm / rpm | 1795/1500 |

| Fuel type | diesel |

| Euro standards | Euro 3 |

| Weight, kg | 1065 (dry) |

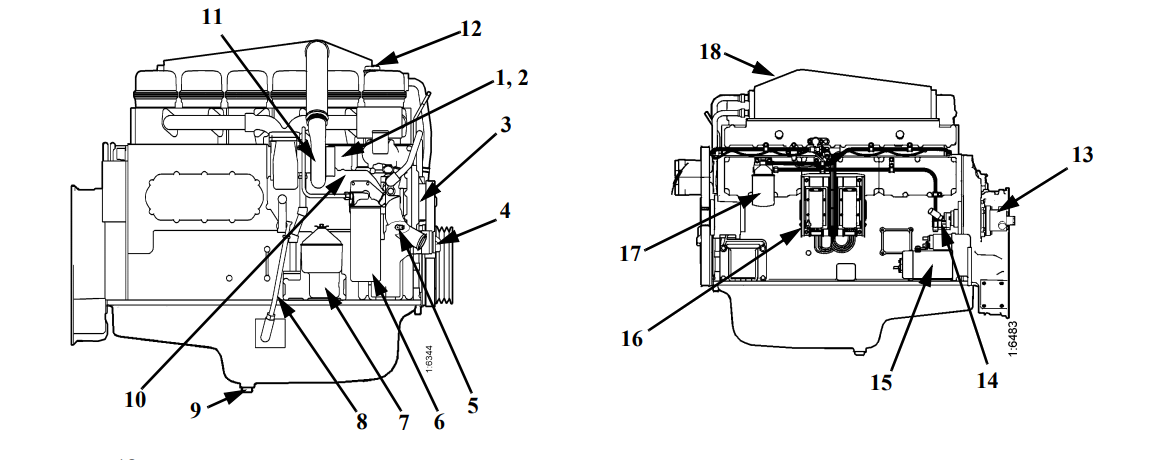

DC12 motor schematic

- Rating plate;

- The engine number is stamped on the cylinder block;

- Coolant pump;

- Automatic belt tensioner;

- Draining coolant;

- Oil filter;

- Oil filter unit;

- Engine oil dipstick;

- Draining engine oil;

- Oil heat exchanger;

- Turbocharger;

- Oil filler neck;

- Hydraulic pump;

- Fuel pump with hand pump;

- Starter;

- S6 control unit;

- Fuel filter;

- Radiator for intercooler.

Major progress has been made in reducing the toxicity of harmful emissions in order to meet the stringent requirements of environmental standards in almost all markets. At the same time, when it comes to Scania industrial and marine engines, high quality standards are ensured in terms of dynamic performance and fuel efficiency.

The engine has an Electronic Management System (EMS) with unit injectors (PDE) to ensure that the correct amount of fuel is delivered to each cylinder in a timely manner under all operating conditions. The EMS system consists of a control unit (S6) and sensors for speed, charge air temperature and pressure, coolant temperature, accelerator / throttle pedal activation oil pressure, which continuously send signals to the control unit. Using this input and the programmed control software, the correct fuel quantity and correct injection time are calculated for each unit injector under the specific operating conditions.

Explanation of DC 12 markings

| DC | Diesel engine with turbocharger and air-cooled intercooler. |

| 12 | Total working volume, dm3. |