All DAF MX engines are the result of DAF’s efforts to develop heavy-duty diesel engines using the latest manufacturing technologies and design methods. The compact design and the latest materials allow for a reduction in weight while maintaining maximum service life, while high performance and significant torque ensure the DAF MX 265’s special driving conditions.

Diesel engines of the DAF MX 265 series are six-cylinder, in-line, 24-valve, turbocharged and intercooled with a volume of 12.9 liters. Equipped with the SCR (Selective Catalytic Reduction) system, which allows to achieve the emission level of harmful emissions in the exhaust gases, which meets the environmental standard of Euro 4.

A distinctive feature of DAF MX engines is that they can be equipped with an automatic shutdown system. It works as follows: when the car is idle for more than five minutes, the engine is automatically shut off.

The high torque (from 1775 to 2500 Nm) of DAF MX 265 engines in relation to the low speed (1000-1410 rpm) allows the use of a gearbox with a lower number of speeds, which gives the motor maximum performance capabilities. These engine modifications are installed on DAF trucks of the CF85 and XF105 series.

Specifications

| Manufacturer | DAF |

| Also called | MX 265 |

| Configuration | inline turbocharged diesel |

| Number of cylinders | 6 |

| Firing order | 1-5-3-6-2-4 |

| Piston stroke, mm | 162 |

| Cylinder bore, mm | 130 |

| Displacement, cc | 12900 |

| Power output, hp | 360 |

| Compression ratio | 17,7:1 |

| Torque output, Nm / rpm | 2000 |

| Euro standards | Euro 4 |

| Weight (dry) | 1200 kg |

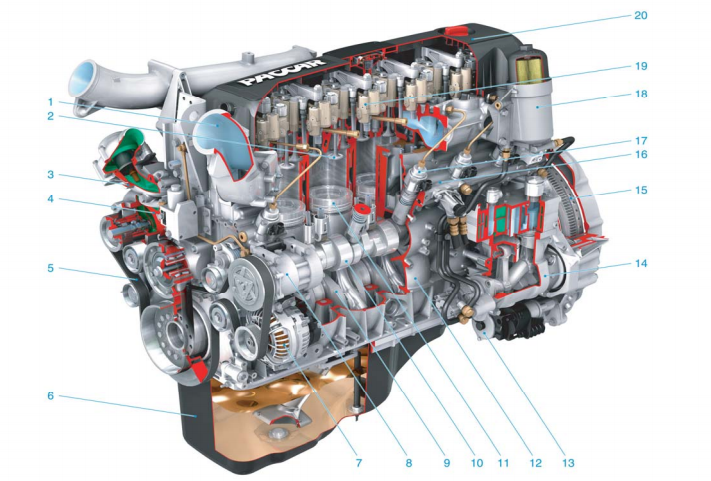

Main engine parts

- Air line

- Valve

- Thermostat cover

- Water pump

- V-ribbed belt

- Oil sump

- Generator

- Air conditioning compressor

- Crankshaft

- Camshaft

- Piston

- Engine block

- Engine starter

- Air Compressor

- Flywheel

- Low pressure fuel line

- Pump block

- Fuel filter

- MX motor brake

- Cylinder head cover

For the first time in the industry, fully insulated wiring on the engine block. This ensures that the wires and connectors are securely connected to the engine block. Well-protected wiring guarantees high reliability and durability.

Optimized the new MX engine brake. It now develops a braking force of 360 kW. And the best news is that three-quarters of that power is available at low revs (from 1500 rpm). The controls are optimized and run smoother.

The new MX 265 engine is equipped with a high volume synthetic cast sump. Its new shape reduces vibration as well as engine noise. The new engine is equipped with a combined fuel filter, heater and water separator to optimize uptime and minimize maintenance costs.

The advanced unit provides a smooth ride and the necessary power indicators. An optimized injection system, a unique exhaust manifold (fully insulated) and new pistons significantly reduce fuel consumption. As a result, the turbine speed increases and the boost pressure increases. Thus, it is possible to increase the speed of rotation of the turbine without a sharp increase in the volume of exhaust gases. The air coming from the compressor needs to be cooled. For this, an air cooler, the so-called intercooler, is integrated into the engine design.

Explanation of DAF MX 265 markings

| MX | 12.9 liter engine family |

| 265 | Engine power, kW – 265 |

DAF is the first company in the automotive industry to use thermal encapsulation not only for a turbocharger, but also for an exhaust system. This results in even more “airy” handling by increasing turbo efficiency and improved combustion. The MX 265 engine has been upgraded to reduce fuel consumption and CO2 emissions by 3%.

The service interval of the truck’s power plant when using synthetics is 150,000 km, when using mineral oils – 90,000 km. In Russian conditions, this figure is reduced to 60,000 km of run.